Explanation of functions

Machine types

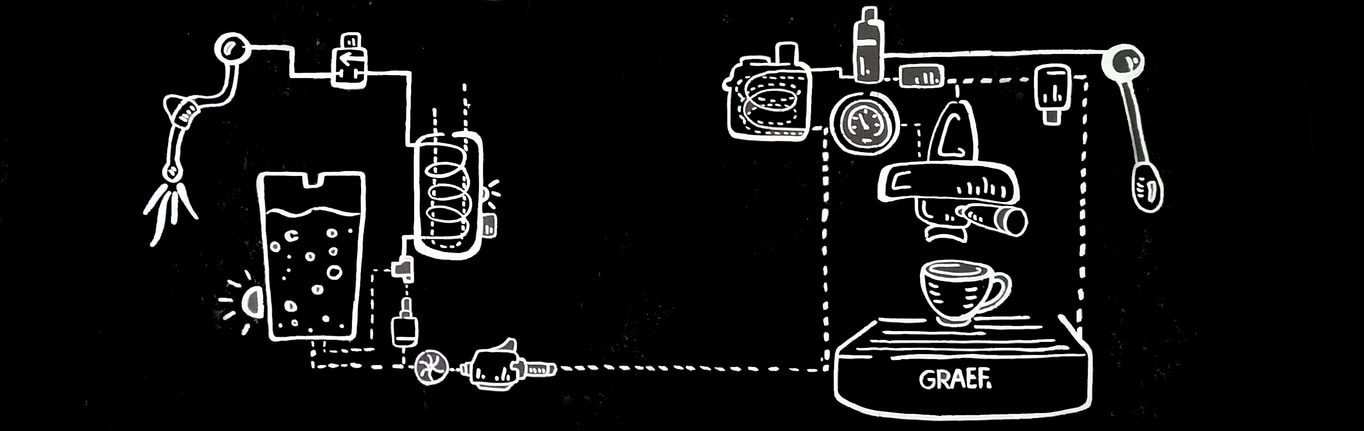

Thermoblock

Like in an instantaneous water heater, cold water is pumped through a heated Thermoblock and is heated.

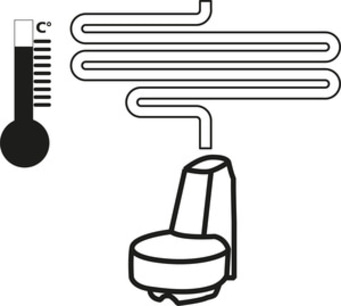

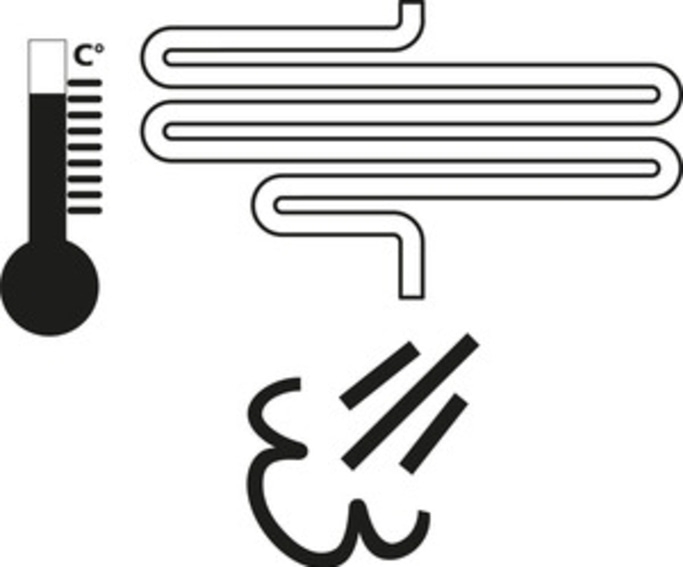

Thermoblock brewing unit

Made of aluminium pressure cast with inside lines made of stainless steel.

Thermoblock coffee

Made of massive aluminium pressure cast with inside lines made of stainless steel.

Espresso machines with Thermoblock have no water boilers that have to be heated. For this reason they are ready to use faster. In the Thermoblock the water is pumped through the spiral water pipe made of stainless steel, and thus can be heated very quickly to coffee temperature. The heating element is located inside the Thermoblock. It needs only a relatively short period of heating - and after one or two empty draws, the Espresso can be prepared. Graef machines use Thermoblocks made of aluminium die cast with integrated stainless steel pipes only.

Thermoblock steam

Made of aluminium pressure cast with inside lines made of stainless steel.

Professional brewing group

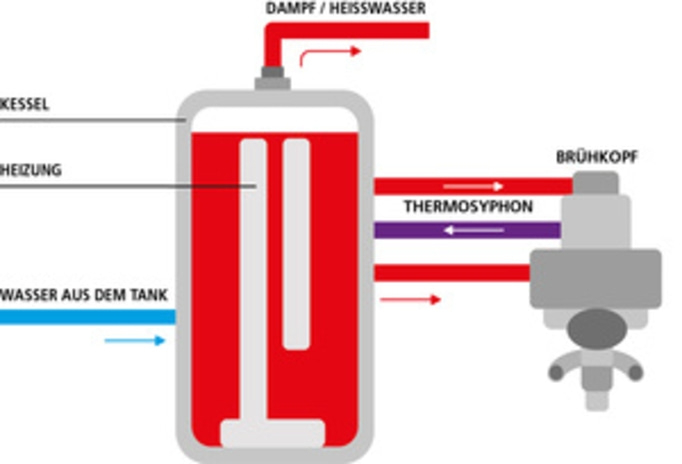

Cold water from the tank is pumped into the kettle and is passed on the brewing unit. In normal operation, the water reaches a temperature of approx. 106 deg. C to 115 deg. C. For steam removal, an additional heating to approx. 130 deg. C is required. The thermosyphon is used for actively heating the heavy brewing group and/or the brewing unit. For this purpose, the heated water is passed to the brewing unit, looses heat there and returns to the kettle with lower temperature.

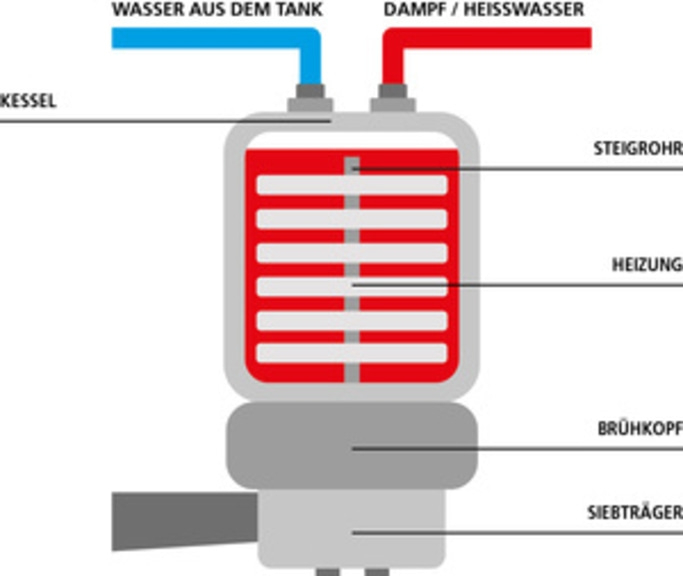

Machines with kettles

By means of the electrically heated kettle, the cold water from the tank is heated and is passed to the brewing unit through a riser pipe. In normal operation, the water reaches a temperature of approx. 90 deg. C to 95 deg. C. For steam removal, an additional heating to approx. 120 deg. C is required. In case of larger machines with a kettle, the heating time takes about 15 to 20 minutes because the massing brewing unit and the heavy filter holder reaches the temperature slower. In case of small machines with a kettle, the heating time is reduced to approx. 10 to 15 minutes due to the compact construction.

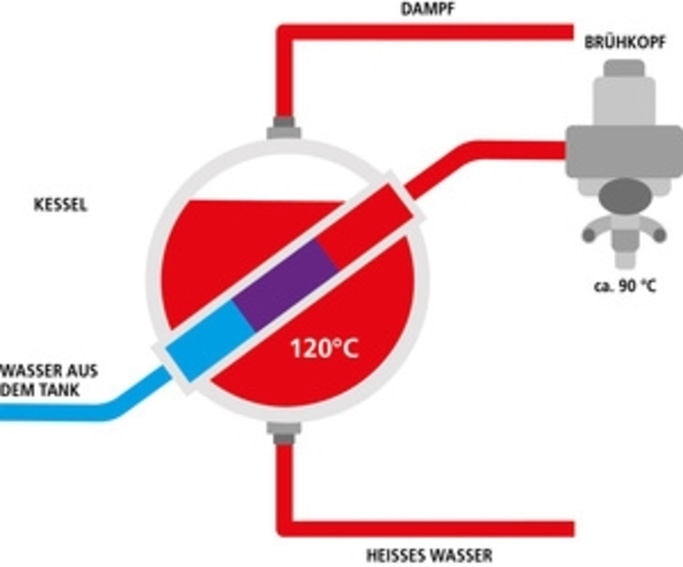

Heat exchanger system

A separate pipe is used to pass the cold water from the tank through hot water of approx. 120 deg. C in the kettle. Thus, it is heated to the ideal temperature of 90 deg. C to 95 deg. C. In this system, the thermosyphon ensures the active heating of the brewing unit again.

Source for the texts: “Fascinating Espresso machine” by Dimitrios Tsantidis